Sustainability

Biomass balance

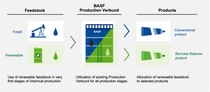

Our biomass balance (BMB) approach for more sustainable coatings, adhesives, construction and fiber bonding materials is an innovative drop-in solution. It empowers our customers to reduce their carbon footprints by up to 100%* – without requiring any reformulations or changes to existing manufacturing processes.

*Taking biogenic CO2 savings into account.

Benefits of biomass balance

- Significantly reduced product carbon footprint

- Replaces fossil resources during production with renewable raw materials

- Reliable quality, identical product performance

- Closed chain of custody certified by independent parties

Similar in concept to green energy, just for chemical production

In the BMB approach, renewable resources, such as bionaphtha or biomethane derived from organic waste, and crops or vegetable oils are used as feedstock in the initial steps of chemical production for our dispersions and construction additives. The amount of biobased feedstock is then allocated to specific products sold by means of a certified method. Biomass-balanced solutions help significantly reduce CO2 emissions and save fossil resources – without compromising performance.

Recognized standards for certification

BASF’s biomass-balanced products are certified according to recognized standards: International Sustainability and Carbon Certification (ISCC Plus) or the certification scheme of REDcert, the organization for sustainably produced biomass (REDcert2).

Certified production

For our dispersions and construction additives, our production sites in Ludwigshafen and Trostberg (Germany), Hamina (Finland), Heerenveen (Netherlands), Castellbisbal and Tarragona (Spain) are all officially certified to produce BMB products.

To explore specific solutions for your products, please get in touch with your BASF account manager.

More about biomass balance solutions in our industries

Discover

Results: 8

Ways to reduce your carbon emissions

Meeting the growing demand: BASF production sites in Heerenveen and Trostberg receive biomass balance certifications

Sustainability meets Adhesives

Biomass Balance Solutions for Architectural Coatings and Construction

Case Study “Save up to 50% CO2 of your EIFS”

In this case study you will learn how the Biomass Balance Approach works and what the benefits are.

Discover more sustainable solutions

Go to industries

Contact us

Not found what you were looking for? Reach out to us for assistance.

Subscribe to our News-Service

Don’t miss the latest news on web seminars, sustainability, regulatory and product innovations.

.jpg)