MyIndustryWorld

Glass Fibers

A wide variety of construction applications use nonwovens and fabrics based on glass fibers, or yarns. The substrates serve as support layers, facings, coverings or reinforcements. Depending on the application and processing requirements, our tailor-made binders ensure that the substrate provides sufficient mechanical performance and offers special resistance to heat, water, solvents or environmental stress.

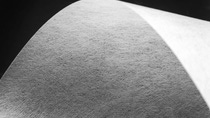

Glass fiber nonwovens

Glass fiber nonwovens are used as support layers for vinyl and carpet-flooring tiles or for bituminous roofings. Additional applications include robust wall coverings and facing layers for mineral wool mats, construction boards, or fiber-reinforced plastic parts.

Glass yarn fabrics

Fabrics made from glass yarn are used as patterned wovens for high-quality wall coverings or as laid or woven meshes for various reinforcing purposes – within external thermal insulation composite systems (ETICS), for example.

Application's products

Discover

Technical Information: Preservation of Polymer Dispersions

Access your PCF data online

How to read your PCF statement

Discover „MyIndustryWorld“ - the new service portal of BASF

BASF at Techtextil 2024: Shaping the future of the textile industry with sustainable solutions

Choose your application:

Contact us

Not found what you were looking for? Reach out to us for assistance.

Subscribe to our News-Service

Don’t miss the latest news on web seminars, sustainability, regulatory and product innovations.