MyIndustryWorld

3D-Lamination

Many good and viable alternatives to solid-wood furniture exist. But using these materials to their full potential often requires solidly bonded components. Make it stick – with our precursors for industrial adhesives.

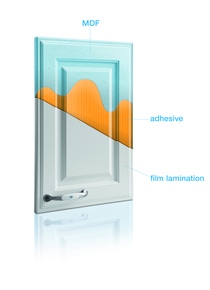

Kitchen and bathroom furniture is often made with wood fiberboards coated with a plastic film. In its most common form, this material is referred to as medium-density fiberboard or MDF. MDF can be formed with three-dimensional profiles and is usually thermolaminated with hard PVC, PET or ABS films.

This process leads to demanding requirements for the adhesives used in the lamination process. To ensure a perfect surface, they must not contain flocking or particles. Strong adhesion to the substrate and excellent cohesion are musts to prevent the film from peeling off and guarantee stable anchoring and long-lasting durability. That’s why adhesives based on polyurethane dispersions are used almost exclusively. Explore our solutions for furniture adhesives!

Requirements for high-quality adhesives used in furniture, such as for 3D lamination:

- Water-based

- Low activation temperature (max. 63 degrees Celsius and max. 55 degrees Celsius high gloss)

- Resistance to high heat (min. 80 degrees Celsius)

- Smooth surface

- High “green strength”

- Non-tack

Highlight products

Discover

Technical Information: Preservation of Polymer Dispersions

How to read your PCF statement

Discover „MyIndustryWorld“ - the new service portal of BASF

Technical Information: Handling and Storage of Polymer Dispersions

Choose your application:

Contact us

Not found what you were looking for? Reach out to us for assistance.

Subscribe to our News-Service

Don’t miss the latest news on web seminars, sustainability, regulatory and product innovations.