MyIndustryWorld

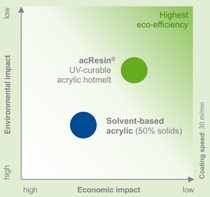

Eco-efficiency analysis

An independently reviewed analysis found that, in comparison with solvent-based adhesives, acResin®-based adhesives are both the less expensive and the more sustainable solution for durable labels.

But what about cost and sustainability?

Adhesive production for durable labels: acResin® versus solvent-based acrylic

Results: acResin® sets new benchmarks in eco-efficiency

- Using acResin® is safer and cleaner for both humans and the environment

- Using acResin® saves money

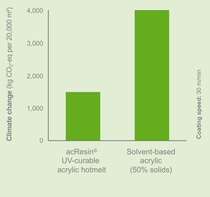

Independent review of eco-efficiency analysis

- System under evaluation:

Production of 20,000 m2 of laminate for durable labels (1.6 m width) - acResin® A 250 UV was compared to a solvent-borne acrylate (50% solid content) with line speed of 30 m/min

- The analysis followed international standards for life cycle and eco-efficiency assessment (ISO 14040:2006, ISO 14044:2006, ISO 14045:2012)

Environmental impact

Climate change (carbon footprint)

With acResin® you can save 2,500 kg CO2-eq per 20,000 m2 which equals 2,500 metric tons CO2 saved per year *

* Assuming 300 days of laminate production for durable labels with a line speed of 30 m/min