MyIndustryWorld

UV-curable technology

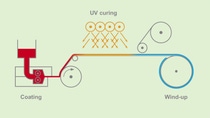

acResin® products contain only pure solids and can be processed immediately on standard hotmelt coaters equipped with commercial UV lamps. No extra drying equipment or flash-off zones are required.

Processing of acResin®

• Easy, cost-efficient curing

• Fast, controllable reaction

• Photoreactive crosslinking

Variable adhesive power

acResin® unleashes its full adhesive power with the right UV curing.

Easy, cost-efficient curing

acResin® can be processed on hotmelt coaters equipped with UV lamps. No solvent or water needs to be removed because acResin® is 100% acrylate. This makes processing far more cost-efficient.

Fast, controllable reaction

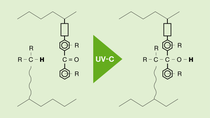

When irradiated with UV-C light, the potentially reactive groups attached to the chains form crosslinks with neighboring polyacrylate chains. The crosslinking reaction is instantaneous, but remains easy to control – it stops as soon as the UV-C radiation is removed.

Photoreactive crosslinking

The photoreactive groups in the acResin® attack the C–H bonds present in neigh-boring chains, resulting in the crosslink structure typical of pressure-sensitive adhesives.

UV-C sensitive photoreactive groups are an integral part of the polymer and therefore non-volatile, which explains why no products of potential toxicological concern are released.

Blending of acResin®

Blending acResin® products with other tackifying resins before curing increases the adhesion of the final product. However, it is important that the selected resins do not absorb significant amounts of UV radiation between 250 nm and 260 nm.

This ensures that sufficient radiation is available for curing. Blending acResin® with modifiers that lack photoreactive groups leads to a certain degree of dilution. This means that a higher dose of UV-C must be used to achieve the required crosslinking density in the blend.